RIBIPACKSEAL

The Ribipack system manages to solve once and for all one of the most critical problems of the food packaging sector: it allows companies to maintain any kind of food container in top hygienic conditions. The solution to this matter is the Ribipack Seal Concept, a sealing method ensuring that container hygiene is maintained even for long periods of time or in case of open storage. The Ribi sealing, initially conceived for empty glass bottles, has also been developed for both empty and full glass jars, tins and PET containers.

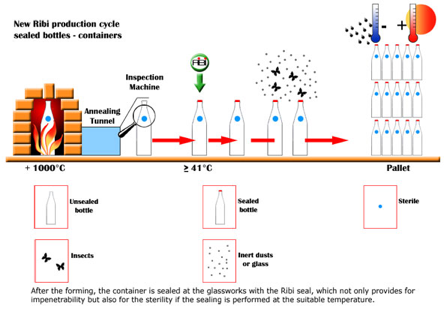

The Ribipack system consists in the sealing of glass containers during manufacturing, through the application of a special film that will automatically be removed immediately before the container is about to be filled at the filling line. The sealing film is applied onto the container after the production and inspection stages, in the cooling section of the glassworks, once glass has reached a temperature of 41ºC and is virtually sterile.

Container contamination starts when the temperature drops below 20°C and continues during the whole logistic process (handling, palletizing, storage and transportation) from the glassworks to the bottling company.

The RIBI seal creates a physical barrier against moisture generation inside glass containers, thus avoiding microbiological contamination and preventing intrusion by foreign bodies such as insects and dust.

The Ribipack sealing machine C0-M1 performs a high-speed fully automated industrial process; it is placed in the cooling section of the glass factory, next to the quality inspection sector.

The machine is available as a standalone version, mounted on a SGCC chassis, or as a sealing module integrated with existing quality inspection machines.

The sealing head is available in a Round Ring Edge version (mostly for bottles), and in a Universal Ring Edge version that can process both round ring edge and sharp ring edge seals (mostly for jars).

The sealing head and accessories are available in different formats, each covering a different range of seal sizes to meet the client’s specific requirements.

The sealing machine can also be provided with an additional optical control module which checks the quality of the seal application.